Dynamic Work Instructions? Yep.

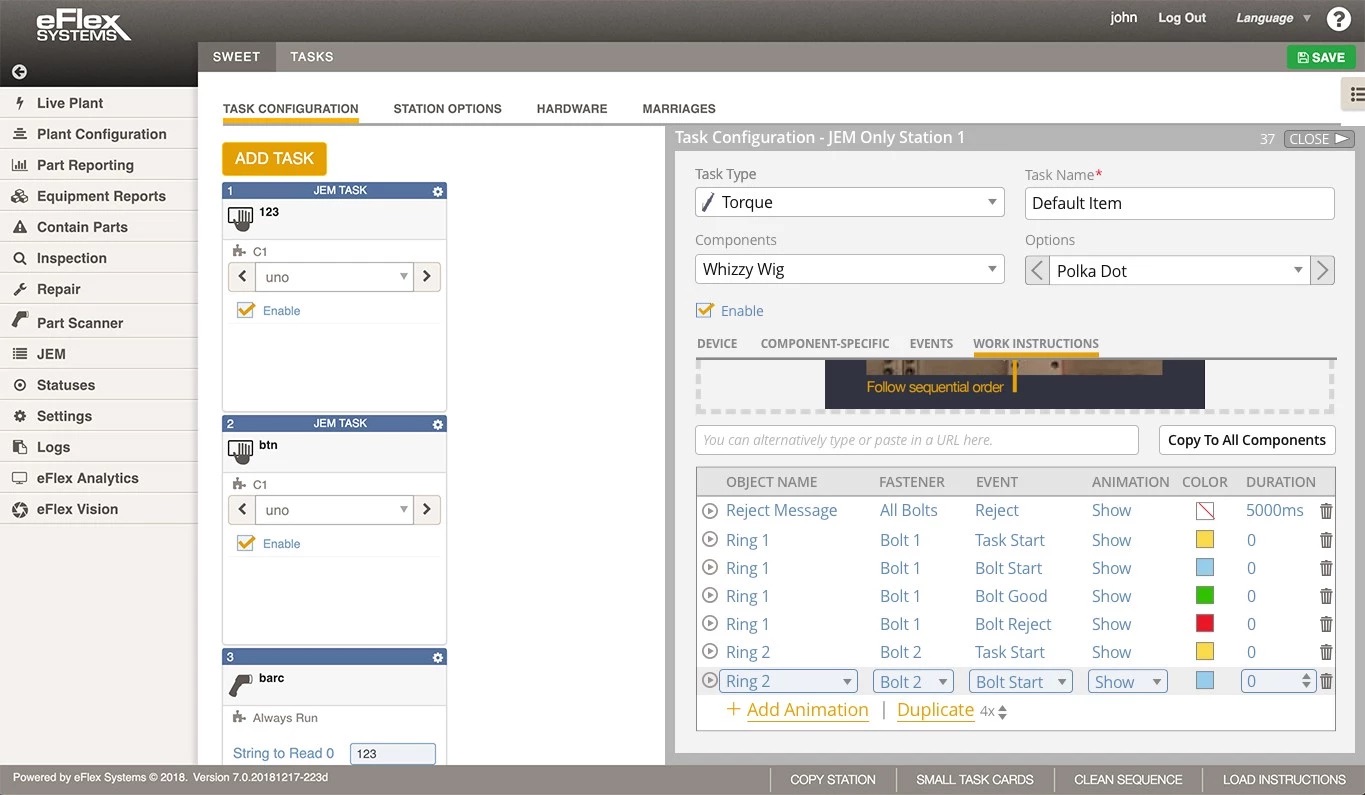

Using the above configuring example, let's now take work instruction creation a step further and examine dynamic work instructions (DWI) more fully. The above mockup shows a dynamic work instruction as it's created in the Work Instruction Editor. Basically, how the process plays out from scratch, first, a new work instruction is created—or an existing work instruction is duplicated as a template to create a like work instruction. Images are imported. Text, lines, shapes, and icons applied. All editing applied. Items grouped. Items locked. And to make an item dynamic, simply give it a DYNAMIC OBJECT NAME in its configuration settings and that makes it a dynamic object—able to be manipulated by task events actions.

Once created it's accessible to be imported into a task. And being a DWI each dark gray ring around each bolt is an individual dynamic object, as is the "Big Mistake!" text box—all with "Start Hidden" checked. All these dynamic objects do not show when the task starts, but show when/if triggered by an action event (e.g. Start, Pass, Reject). On top of these work instruction events, the same action might also simultaneously trigger task events (show a different work instruction) and/or station events (turn on a physical warning light, sound a warning beep).

The event configuration above—when duplicated nine more times—illustrates a torque task that when started all the dynamic objects are hidden. Upon Start (of the task) a yellow ring shows around all the bolts, except the first bolt is blue—the current bolt to fasten. Set upper and lower torque limits determine if a bolt gets rejected. If the torque is within limits, the blue ring turns green (Pass) and the next intended bolt ring turns blue. If a torque is out of limits or the wrong bolt is tightened the ring will turn red, the "Big Mistake!" message shows and any other reject event triggers.

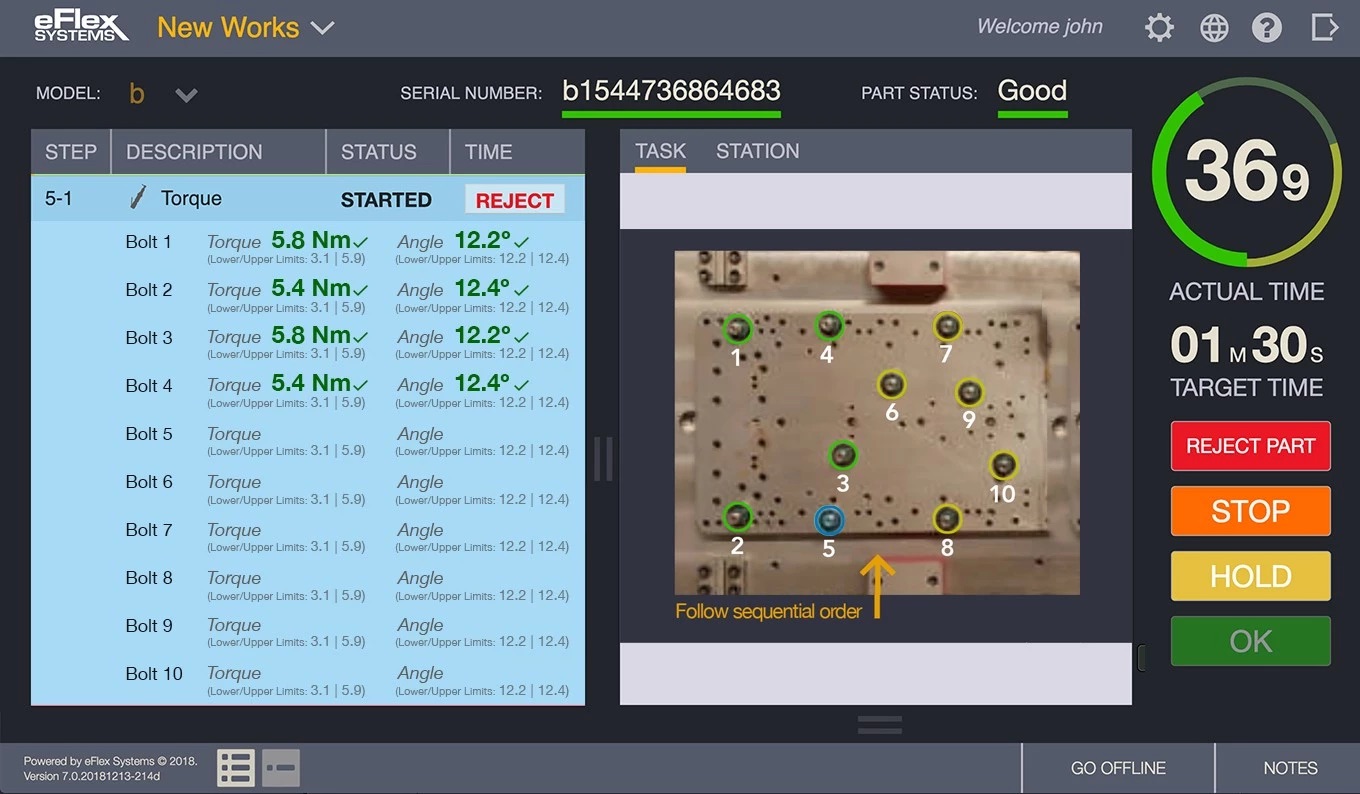

Below is how this plays out on JEM. The first illustration shows the task process has started, Bolts 1-4 were successfully fastened (see the Torque and Angle results on the List panel), and Bolt 5 is identified.

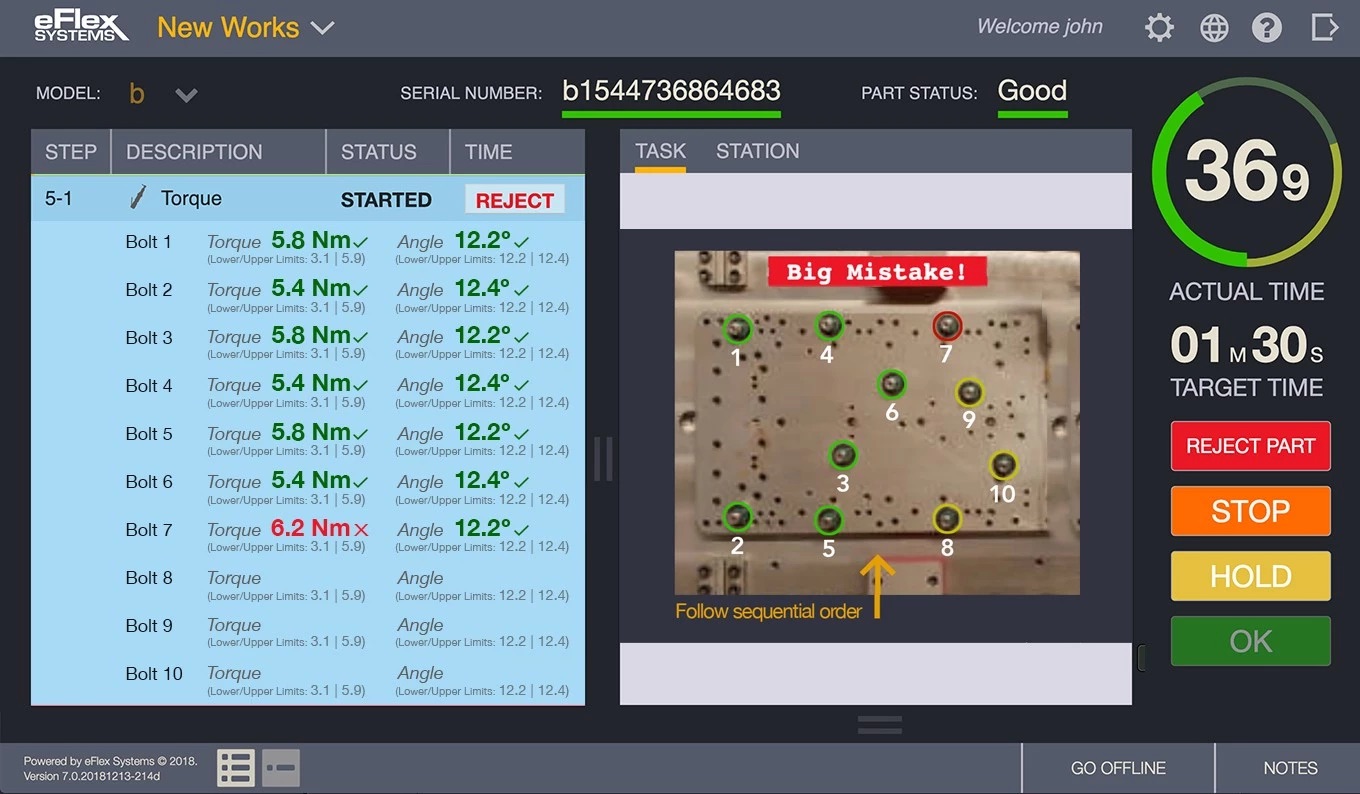

The second illustration shows Bolts 1-6 successfully fastened, but Bolt 7 was fastened too tightly. Bolt 7 ring turns red, the "Big Mistake!" warning shows. After a configured x-amount of time (e.g. 5 seconds) a "task event" triggers showing a different work instruction, while a "station event" has turned on an andon light and blasted a horn.

The second illustration shows Bolts 1-6 successfully fastened, but Bolt 7 was fastened too tightly. Bolt 7 ring turns red, the "Big Mistake!" warning shows. After a configured x-amount of time (e.g. 5 seconds) a "task event" triggers showing a different work instruction, while a "station event" has turned on an andon light and blasted a horn.

This shows the possibilities that work instructions and particularly dynamic work instructions possesses. However, before any of this hits the plant floor they have to be approved. And this too can be done right within the application.

Conclusion

Dynamic Work Instructions are a huge feature. As said in JEM, a lot of companies now created digital work instructions, but few have a robust editor, and no other work instructions have the dynamic objects. That in and of itself is a big gamechanger. In design, it's theoretical as I don't have the actual tools myself, but makes sense. However to see it in action, first with dev testing, then live at a show is awesome—and very rewarding. See eFlex's